Máquinas precisam ficar em boa condição para funcionar bem em fábricas e oficinas. O petróleo é realmente importante. Ela mantém peças de máquina em movimento suave e permanece frio. Mas o petróleo pode ficar confuso com coisas como terra, água ou gás ao longo do tempo. Isso pode prejudicar máquinas. É por is so que uma máquina de purificação de petróleo é tão útil! Limpa o petróleo, faz o equipamento durar mais, e economiza dinheiro em reparações. Este artigo fala sobre como uma máquina de purificação de petróleo funciona, seus benefícios e por que é incrível para manter as máquinas funcionando bem.

O que são purificadores de petróleo?

Uma máquina de purificação de óleo é uma ferramenta legal que limpa os óleos usados em máquinas. Ele remove lixo como terra, água e gases. O petróleo desordenado pode causar problemas, como máquinas quebradas ou desgastadas rapidamente.

Tipos de Purificadores de Petróleo

Existem alguns tipos de máquinas de purificação de petróleo, cada uma perfeita para tarefas diferentes:

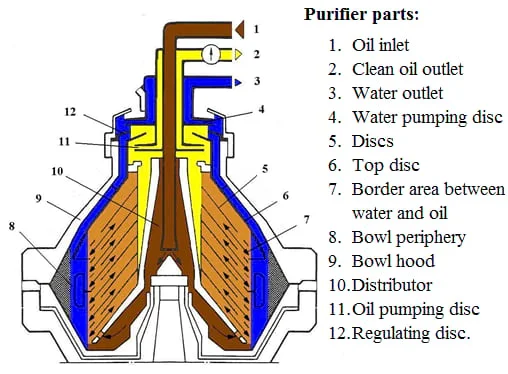

- Purificadores Centrífugos de Petróleo: Esses usam giro rápido para tirar a terra do petróleo. O petróleo gira rápido, coisas pesadas como a terra vão até as margens, e o petróleo limpo fica no centro.

- Purificadores de óleo vazio: Esses usam um vácuo para sacar água e outros lixo. Eles aquecem um pouco o óleo para fazer coisas ruins desaparecerem como vapor.

- Coalescing and Separating Purifiers: Estes são incríveis em separar água do petróleo. Eles fazem pequenas gotas de água maiores, então eles afundam e deixam o petróleo limpo.

Cada tipo faz um trabalho especial. Algumas limpam água, enquanto outras se livram da terra. Isso mantém o petróleo puro e as máquinas felizes.

Como funcionam os purificadores de petróleo?

Uma máquina de purificação do petróleo limpa o petróleo tirando coisas ruins. Usa truques limpos como girar ou poder de vácuo para tornar o petróleo limpo novamente.

Processo de Separação Centrífuga

Máquinas centrífugas de purificação de petróleo giram muito rápido. Coisas pesadas como terra ou água se movem para fora. O petróleo mais limpo fica no meio. Assim não usam filtros de lançamento, então é barato e funciona ótimo.

Filtração e desidratação

Alguns purificadores usam filtros e vácuos. Primeiro, os filtros pegam terra e lixo. Então, um vácuo tira água transformando-a em vapor. Isso assegura que o petróleo permaneça limpo e pronto para máquinas.

Processo de purificação passo a passo

- Procurem o lixo: O petróleo é verificado para encontrar terra, água ou gás.

- Limpar coisas ruins: A máquina de purificação do petróleo usa energia girante ou vácuo para separar o lixo.

- Enviar de volta o óleo limpo: Petróleo limpo volta para a máquina, então funciona bem.

Benefícios de Usar Purificadores de Petróleo

Usar uma máquina de purificação de petróleo traz toneladas de coisas boas para fábricas e máquinas.

Vida Máquina Longer

Petróleo limpo ajuda máquinas a durar muito mais. Um estudo de 2023 International Journal of Advanced Manufacturing Technology disseram que máquinas com máquinas de purificação de petróleo duraram até 30% mais do que aquelas sem. Isso economiza muito dinheiro em reparações e novas partes. O petróleo sujo causa esfregamento, calor e uso, o que quebra máquinas mais rápido. Uma máquina de purificação de petróleo mantém o petróleo limpo, então partes ficam seguras e trabalham por anos. [Fonte: Springer – International Journal of Advanced Manufacturing Technology]

Baixos custos de reparação

Uma máquina de purificação de petróleo economiza dinheiro em reparações. O petróleo desordenado leva a mais quebra e mudanças de petróleo. Com petróleo limpo, você repara menos e gasta menos. Isso mantém as máquinas funcionando sem parar para reparações.

Melhor Performance de Máquina

Petróleo limpo faz as máquinas funcionar suavemente. Ele corta o esfregamento e impede os quebramentos. Máquinas funcionam o melhor deles, fazendo mais coisas com menos espera. Um relatório de 2022 do Instituto Nacional de Normas e Tecnologia (NIST) mostrou que fábricas que utilizavam máquinas de purificação de petróleo tinham 15% melhor desempenho de máquinas e 20% menos tempo de descanso. [Fonte: NIST – Instituto Nacional de Normas e Tecnologia]

Ajudar o Ambiente

Máquinas de purificação de petróleo deixam o petróleo durar mais, então você joga menos. Isso é ótimo para o planeta. Ela economiza petróleo e corta os resíduos, tornando as fábricas mais ecológicas. Em 2023, o Programa das Nações Unidas para o Ambiente (UNEP) disse que as indústrias que utilizam máquinas de purificação do petróleo cortam os resíduos de petróleo em até 40%. Isso ajuda a atingir metas verdes e mantém o ambiente mais limpo. [Fonte: UNEP – Programa das Nações Unidas para o Ambiente]

Ourun. s Soluções de Purificador de Petróleo

Em Shenyang Ourun Technology Co., Ltd.construímos máquinas incríveis de purificação de petróleo para indústrias como trabalho de metais, carros e centrales elétricas. Nossas ferramentas mantêm máquinas funcionando bem, gerenciam bem o petróleo, e reduzem pausas.

Produtos-chave

- CXJ Disc-Centrifugal Oil Purifier: Esta máquina de purificação do petróleo usa girar para limpar o petróleo sem desperdiçar filtros. É perfeito para óleos hidráulicos e lubricantes em muitas indústrias.

- ZYD Double Stage Vacuum Transformer Oil Filtration: Este sistema limpa o petróleo transformador. Ela remove água e terra, mantendo o petróleo ótimo para máquinas.

- TY Vacuum Turbine Oil Purifier: Construída para óleos de turbina, esta máquina de purificação de óleo usa um vácuo para limpar água e gás, mantendo as turbinas fortes.

Características-chave de Ourun s Purificadores de Petróleo

- Óptima potência de limpeza: Nossas máquinas centrífugas de purificação de petróleo se livram de lixo rapidamente, mantendo máquinas em grande forma.

- Continua indo sem pararNossas ferramentas funcionam por muito tempo sem parar, então suas máquinas ficam ligadas.

- feito para encaixar: Fazemos máquinas de purificação de petróleo que correspondam ao que sua indústria precisa, dando-lhes opções.

Aplicações através das indústrias

As máquinas de purificação do petróleo de Ourun funcionam em muitas áreas, mantendo as máquinas limpas e duras.

Geração de Energia e Utilidades

Em centrales elétricas, máquinas de purificação de petróleo limpam turbinas e óleos hidráulicos. Isto impede desligações inesperadas e mantém as máquinas confiáveis.

Fabricação e máquinas pesadas

Fabricas com grandes máquinas usam máquinas de purificação de petróleo para manter o petróleo limpo. Isso ajuda o equipamento a durar mais, mesmo em condições difíceis.

Operações marinhas e offshore

Naves e plataformas marinhas precisam de petróleo limpo para motores e sistemas. Máquinas de purificação de petróleo mantêm o petróleo puro, cortando o uso em ambientes duros.

Automóvel e Transporte

Os carros e camiões precisam de bom petróleo para os motores. Máquinas de purificação de petróleo mantêm lubrificantes limpos, aumentando o uso de combustível e baixando os custos de reparação.

Mantenimento e Solução de Problemas

Cuidar de sua máquina de purificação de petróleo é muito importante para mantê-la funcionando bem. Aqui estão alguns conselhos para mantê-lo em forma superior.

Praticas de Mantenimento Regulares

- Trocar filtros no tempo: Verificar filtros Muda-as com base no quanto você usa a máquina ou o quanto o petróleo é sujo.

- Verifique o Sistema: Olhem para a máquina de purificação de petróleo regularmente para ter certeza de que está correndo bem.

Issas Comum e Soluções

- Não limpar bem: Se a máquina de purificação do petróleo não está limpando adequadamente, os filtros podem ser bloqueados, ou partes podem ser esgotadas. substituí-los para consertá-lo.

- Máquina forte ou tremenda: Ruídos ou tremor podem significar que algo está errado. - Certifique-se de que a máquina está configurada corretamente e as partes estão bem.

- Fugas de Petróleo: As fugas podem acontecer por causa de focos ruins. Verifique e substitui focos ou gasquetes para os deter.

Conclusão

Uma máquina de purificação de petróleo é uma necessidade para manter máquinas em forma incrível. Limpa o petróleo, evita quebramentos e economiza dinheiro em reparações. O petróleo limpo significa que as máquinas duram mais e funcionam melhor. Seja você esteja em usinas, fábricas, navios ou carros, as máquinas de purificação de petróleo de Ourun s ão perfeitas para manter o petróleo puro e as máquinas funcionando suavemente. Com nossas ferramentas, você tem um grande desempenho, menos espera, e um planet a mais limpo.

Perguntas frequentes

Q1: Quantas vezes uma máquina de purificação de petróleo deve ser verificada?

A: Verifique sua máquina de purificação de petróleo a cada três a seis meses. Depende de quanto você o usa e onde é usado. Os cheques regulares mantêm-no funcionando bem.

Q2: Uma máquina de purificação de petróleo pode limpar todos os tipos de óleos industriais?

A: Sim, a maioria das máquinas de purificação de petróleo pode limpar muitos óleos, como hidráulicos, turbinas ou aceites de engrenagem. Escolha uma que corresponda ao tipo e espessura do seu petróleo.

Q3: Que sinais mostram que uma máquina de purificação de petróleo precisa de ser corrigida?

A: Procurem uma limpeza ruim, ruídos estranhos, tremendo ou vazamento. O cuidado regular pega esses problemas cedo e mantém sua máquina funcionando bem.