As a technical engineer with over a decade of experience in the hydraulic system field, I’ve witnessed countless equipment breakdowns caused by oil contamination. Just last week, I handled an emergency repair at an automotive stamping plant – a million – dollar hydraulic press suddenly shut down. When we disassembled it, we found three deep scratches on the servo valve spool caused by metal particles, and the cost of replacing parts and the loss from downtime exceeded 200,000 yuan. Such cases are by no means rare in the industry.

1. Don’t Be Fooled by Appearances: 70% of Failures Have Their Roots in Oil

Many of my peers rush to replace pumps and valves when they hear equipment making abnormal noises or notice unstable pressure, but they overlook the most basic oil testing. The data analysis from our laboratory over the past three years shows that 70% of hydraulic system failures can be directly traced to oil contamination. Excessive moisture can cause the oil film to break, accelerating component rust; solid particles can wear the mating surfaces like sandpaper, leading to a sharp increase in internal leakage; and sludge and colloid can clog the filter element, causing the system back pressure to rise abnormally.

A case from a construction machinery factory is quite typical: their excavator hydraulic systems failed on average every 3 months, and even after replacing the main pump three times, the problem remained unsolved. When we arrived for an inspection, we found that the concentration of solid particles in the oil, at NAS 8 level, combined with a water content of 0.05%, was equivalent to feeding “sandpaper paste” to the precision components.

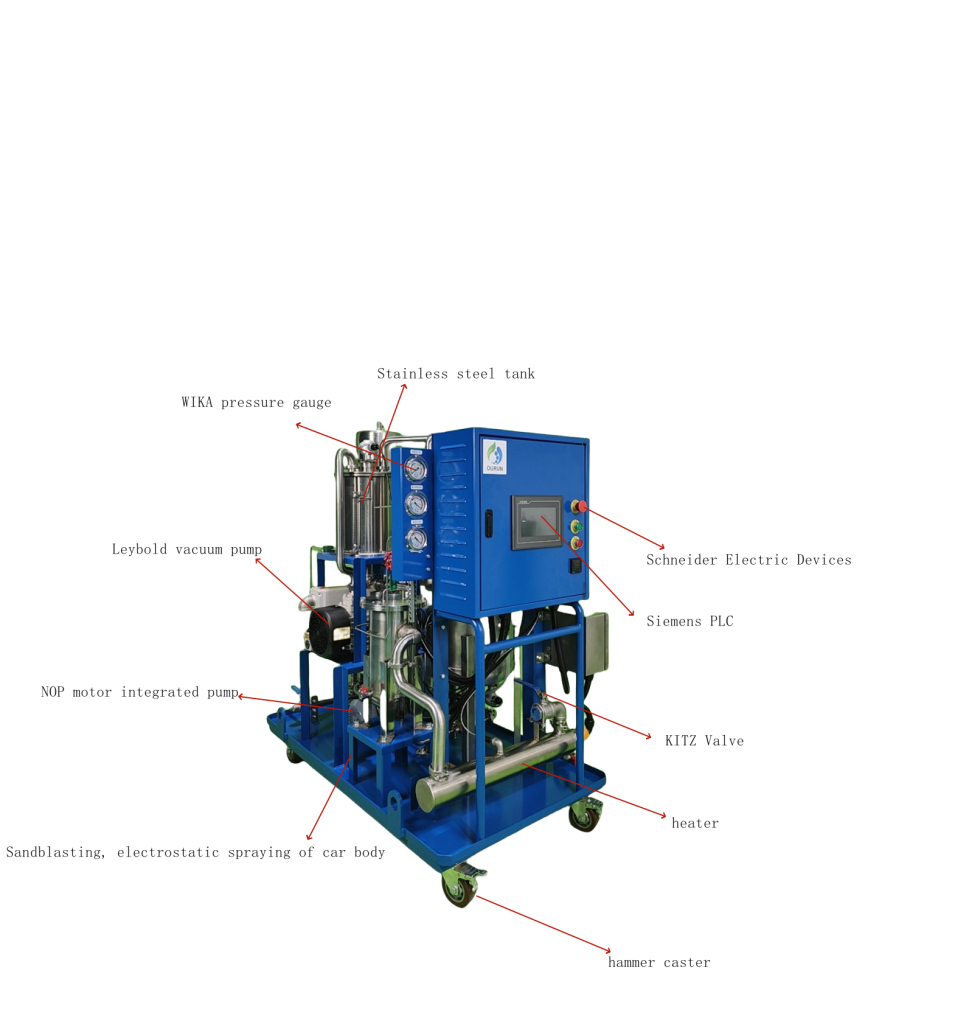

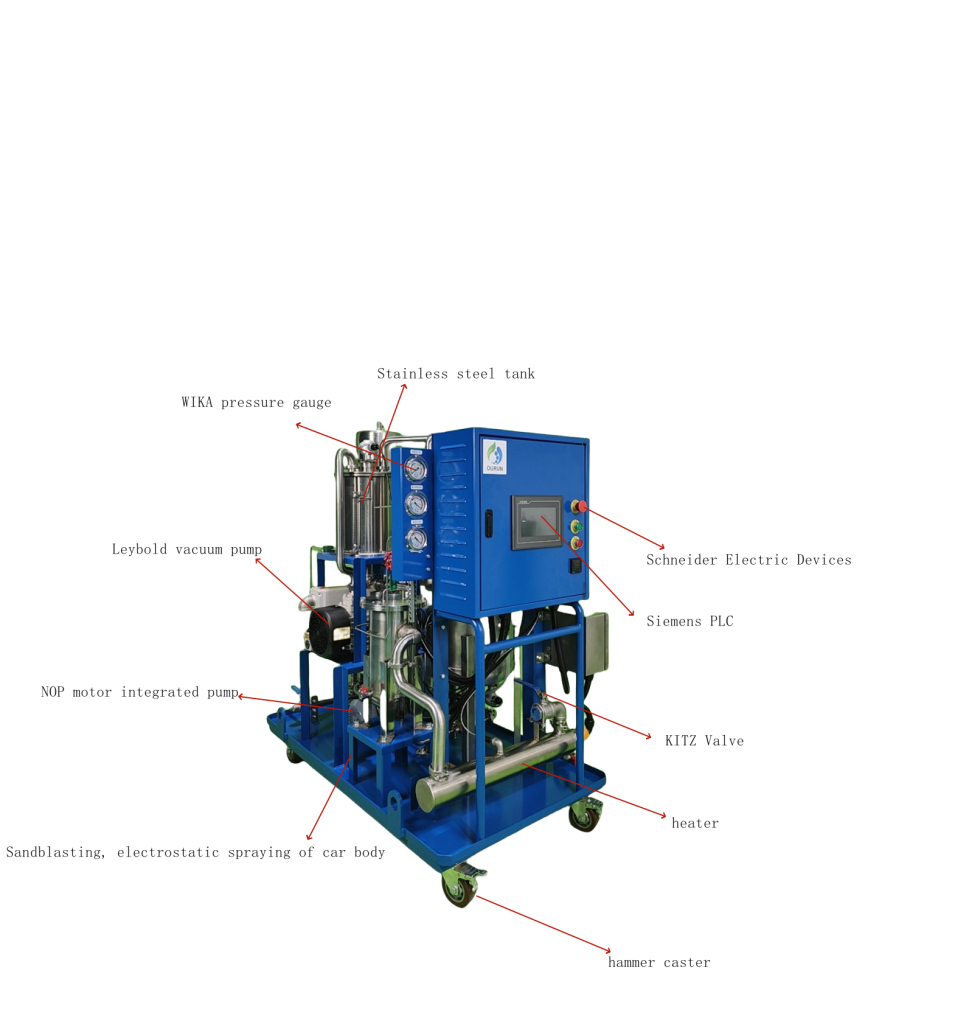

2. The Triple Purification Logic of This Oil Filter – We Tested It for 180 Days

To address such issues, our team tested 23 types of oil filtering equipment and finally settled on this model with “three – stage progressive purification” technology. Its core logic is not simple filtration but solving the contamination chain from the root:

- Pre – treatment Stage: A 10μm metal mesh plus a polymer adsorption layer first intercepts mechanical impurities larger than 10μm and free water. This step alone can solve 60% of the initial contamination problems. In a test at an injection molding workshop, this single stage of filtration extended the oil change cycle from 2 months to 5 months.

- Deep Purification Stage: It uses a gradient – pore glass fiber filter element (with a precision of 3μm to 1μm) combined with coalescence separation technology. We simulated a low – temperature environment of – 15℃ in the laboratory, and it could still separate the emulsified water in the oil to ≤50ppm, which is especially crucial for outdoor equipment in northern regions.

- Vacuum Dehydration Stage: With an ultimate vacuum degree of – 0.098MPa and constant temperature heating at 30℃, it can force the dissolved water to evaporate. Data from the application in a wind power hydraulic station shows that the water content of the anti – wear hydraulic oil after treatment is stably below 30ppm, increasing the hydraulic pump’s lifespan from 12,000 hours to 38,000 hours.

3. Three Practical Suggestions for Technical Peers

- Don’t Blindly Believe in “One – time Filtration”: Our comparative tests in automobile production lines prove that 8 hours of cyclic filtration is 3 times more effective than single filtration. This equipment supports 24 – hour continuous operation, and it is recommended to operate at a ratio of “4 hours of filtration for every 100 hours of operation”.

- Pay Attention to the Hidden Costs of Filter Element Replacement: Its patented self – cleaning filter element design extends the replacement cycle from the conventional 15 days to 60 days. A steel plant calculated that this alone can save 12,000 yuan in consumable costs every year.

- Installation Location Determines 80% of the Effect: The optimal solution is to connect it in parallel to the oil tank return line. We conducted three groups of comparisons: return oil filtration is 40% more efficient in pollution control than bypass filtration, and reduces the risk of pump cavitation by 90% compared to suction oil filtration.

4. 180 – day On – site Test Data Doesn’t Lie

We conducted a set of comparative experiments on the filter press hydraulic system of a heavy machinery factory:

Now the workshop director tells everyone, “This equipment is worth buying. Just reducing downtime by three days has already made up for the cost.”

A Technical Person’s Honest Opinion: When we choose equipment, we don’t fall for gimmicks; we only trust data. If your workshop’s hydraulic system has similar problems, it is recommended to first take an oil sample for contamination testing (we can provide free testing services). Click the link below to obtain the “Hydraulic Oil Contamination Testing Specification” and the detailed technical parameters of this equipment, which include 12 sets of industry data we measured. It might help you avoid the pitfalls we’ve encountered.