Introducción a la recuperación de aceite hidráulico usado

Gestiona maquinaria pesada en industrias donde los sistemas hidráulicos son vitales. Con el tiempo, la suciedad, el agua y las partículas de desgaste se acumulan en el aceite hidráulico. Estos contaminantes dañan el rendimiento y causan reparaciones costosas. ¿Puede limpiar este aceite usado para igualar o incluso superar la pureza del aceite fresco, como las normas ISO 4406? Absolutamente, con métodos modernos de purificación, puede restaurar la calidad del aceite, ahorrar dinero y ayudar al medio ambiente.

Imagine que su equipo funciona más tiempo sin cambios frecuentes de aceite. La recuperación elimina las impurezas dañinas y mejora las propiedades del aceite. A menudo, logra una pureza mejor que el aceite nuevo, como el NAS 1638 Clase 6 o más limpio. Esto reduce el desgaste de las piezas. Funciona bien en la minería, la fabricación y otros campos exigentes donde el tiempo de inactividad le cuesta caro.

Como experto en gestión de fluidos, valoro a los socios que ofrecen soluciones prácticas. Deberías salir. Nuestrounun equipo centrado en herramientas innovadoras de purificación de aceites. Diseñan sistemas para la deshidratación al vacío y la filtración precisa, manteniendo sus operaciones sin problemas. Sus habilidades radican en adaptar equipos para tareas difíciles, ayudándole a reducir los costos del petróleo mientras cumple con estrictos objetivos de pureza. Trabajan estrechamente con usted, resolviendo problemas con un enfoque personal. Esto los convierte en la mejor opción para profesionales que necesitan una recuperación fiable.

Los contaminantes en el aceite hidráulico usado provienen del polvo, el desgaste del sistema o la exposición al calor. El agua causa oxidación. Las partículas desgastan partes. El aceite espesado de la oxidación ralentiza el flujo. Al abordar estos problemas directamente, la recuperación convierte los residuos en un recurso útil. Se alinea con su objetivo de operaciones eficientes y de alta calidad.

El proceso de reclamación

Con el potencial de la recuperación claro, exploremos cómo funciona. Empieza probando el aceite para comprobar los niveles de contaminación. Herramientas como contadores de partículas o espectrómetros muestran lo que está mal. Este paso identifica problemas específicos, dando forma a su plan de purificación.

A continuación, filtra las partículas sólidas. Los filtros de alta calidad capturan bits tan pequeños como 3 micras, mucho más finos que los sistemas básicos. La deshidratación elimina el agua. Los métodos de vacío evaporan la humedad a bajo calor, protegiendo los aditivos de aceite. La desgasificación extrae gases que podrían dañar las bombas.

Por último, puede agregar refuerzos para mantener el espesor del aceite y la protección contra el desgaste. Los sistemas de múltiples pasos combinan estas acciones para obtener mejores resultados. Puede mejorar el aceite de ISO 22/20/18 a ISO 15/13/11 o mejor. Esto aumenta la fiabilidad del sistema.

Este proceso limpia el aceite y evita problemas futuros cuando forma parte de su mantenimiento regular. Controla la calidad del fluido, reduciendo averías repentinas.

Pasos clave explicados

Empieza tomando muestras de aceite. Los laboratorios prueban agua, acidez y partículas para establecer una línea de base.

La filtración utiliza elementos especiales para separar el agua y las mallas finas para los sólidos. La deshidratación al vacío calienta suavemente el aceite para eliminar la humedad sin dañarlo.

Los filtros de pulido luego limpian el aceite a niveles minuscules. Esta secuencia asegura una completa purificación, preparando el aceite para su reutilización en sus sistemas hidráulicos.

Soluciones para la recuperación de aceite hidráulico

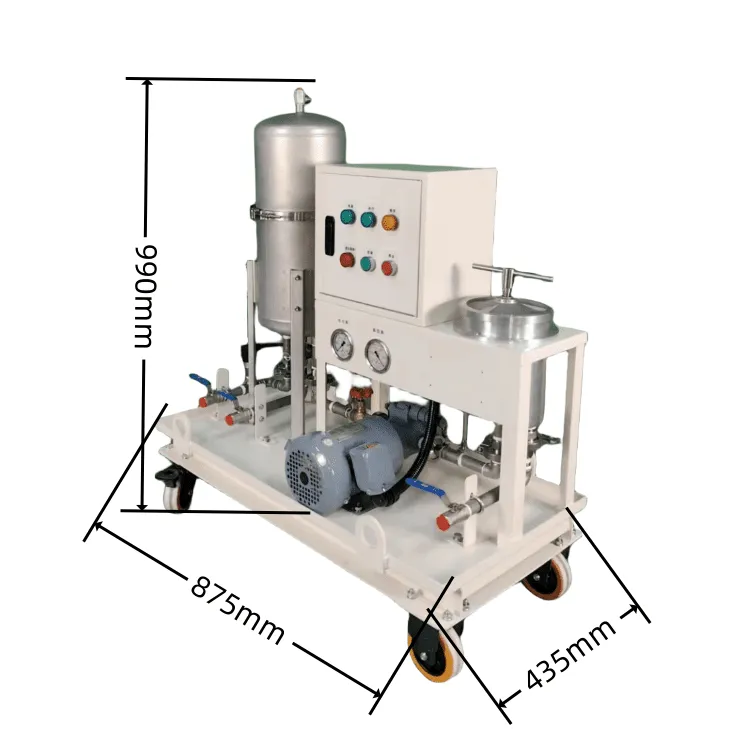

Conociendo el proceso, necesitas un equipo fuerte para que suceda. Los purificadores especializados satisfacen las necesidades de entornos industriales difíciles. Ofrecen un alto flujo y una limpieza precisa.

Una gran elección es la Purificador de aceite de precisión de la serie IOPFiltra hasta 3 micrómetros con caudales de hasta 500 litros por minuto. Es una opción certificada para mantener los estándares ISO en sus sistemas.

Las unidades de vacío también proporcionan la eliminación de agua profunda, bajando los niveles por debajo de 100 ppm. Los separadores centrífugos eliminan rápidamente los contaminantes más pesados, perfectos para operaciones grandes.

Estas herramientas se adaptan fácilmente a su trabajo, ya sea independiente o parte de una configuración de lubricación más grande. Obtendrá diseños flexibles que coincidan con su equipo, como prensas o cajas de cambios.

Incorporar soluciones en su trabajo

Puede instalar purificadores en el sitio para monitorear y limpiar constantemente. Las configuraciones de bypass le permiten purificar sin detener la producción. Esto mantiene sus operaciones funcionando.

El uso regular mantiene el aceite limpio, deteniendo la acumulación de barniz o lodo. Este enfoque proactivo se ajusta a sus planes de mantenimiento, mejorando el rendimiento en todas sus máquinas.

Ventajas de las soluciones de reclamación

Los beneficios van más allá de la limpieza, afectando directamente sus ganancias. La recuperación de petróleo reduce el uso en un 70-90%. Evita comprar aceite nuevo con frecuencia y reduce los costos de eliminación. Esto ahorra mucho, especialmente en grandes operaciones.

Su equipo dura más tiempo, con piezas que trabajan 5-10 veces más debido a menos desgaste. Un aceite más limpio significa menos averías, reduciendo los costos de reparación y el tiempo de inactividad. En la minería, los camiones de transporte funcionan más suavemente, aumentando la producción.

Medioambientalmente, la recuperación reduce los residuos. Esto respalda sus objetivos verdes y cumple con las regulaciones. Menos aceite eliminado reduce su impacto ambiental.

La fiabilidad es una gran victoria. La calidad constante del aceite evita fallas en sistemas clave como rodamientos o sopladores. Esto garantiza una producción consistente.

Beneficios financieros y laborales

Ahorra dinero con intervalos más largos de cambio de aceite. Esto libera dinero para otras necesidades. Sus sistemas funcionan más fríos y mejor, utilizando menos energía.

En industrias difíciles, estas ventajas le dan una ventaja competitiva. Se enfoca en las tareas principales en lugar de los problemas fluidos.

Estudios de casos y pruebas

Los ejemplos reales muestran lo bien que funciona. En una operación minera, el aceite del camión de remolque estaba sucio con altos recuentos de partículas y agua. Esto causó problemas frecuentes de rodamientos.

Después de la purificación, el aceite supera los nuevos estándares de aceite. El agua cayó por debajo de 200 ppm, y los códigos ISO mejoraron enormemente. El tiempo de funcionamiento de los camiones aumentó un 30% y los intervalos de mantenimiento se duplicaron.

En la fabricación, las prensas hidráulicas tenían un rendimiento lento debido al aceite sucio. La recuperación restableció el flujo de aceite y eliminó las impurezas. El aceite superó los estándares de fábrica. Las prensas funcionaban perfectamente, sin fallas durante meses.

Los datos de estos casos muestran resultados: el recuento de partículas cayó de miles a cientos por mililitro. Esto demuestra que el proceso funciona de manera fiable.

Lecciones de casos reales

Vemos que la acción temprana trae los mejores resultados. Los controles regulares detectan problemas antes de que crezcan, encajando fácilmente en su rutina.

Estos ejemplos abordan sus preocupaciones, desde ahorrar dinero hasta proteger el equipo.

Conclusión y siguientes pasos

Recuperar aceite hidráulico usado es una manera inteligente de lograr una limpieza máxima. Mejora sus operaciones, ahorra dinero y ayuda al medio ambiente. Con métodos precisos y herramientas avanzadas, obtiene aceite que supera los nuevos estándares, protegiendo sus máquinas.

Comience comprobando el estado de su aceite. Entonces, explorar opciones de purificación que le convengan. El uso de estas soluciones lo prepara para el éxito a largo plazo.

Alcanzar al sitio web para asesoramiento o visita el sitio web para soluciones personalizadas.

Preguntas frecuentes

P: ¿Cuánto tiempo tarda en recuperar el aceite hidráulico?

R: Depende del volumen del aceite y los niveles de suciedad. Por lo general, lleva horas a un día. Esto te permite volver al trabajo rápidamente.

P: ¿Qué impurezas puede eliminar la recuperación?

R: Limpia agua, partículas, gases y trozos de aceite espesados. Esto restaura el aceite a un estado limpio.

P: ¿El aceite recuperado es seguro para todos los sistemas hidráulicos?

R: Sí, cuando se limpia de acuerdo con los estándares más altos, funciona bien en muchos sistemas. Cumple o supera las necesidades originales.