Die Reinigung der Ölfilter ist sehr wichtig, damit Maschinen gut funktionieren. Sie helfen, alles reibungslos ohne Schlucken zu laufen. Lassen Sie uns eintauchen, warum sie so wichtig sind und was passiert, wenn Sie ihre Pflege überspringen.

Die Rolle von Ölfilter in Maschinenschutz

Ölfilter wirken wie zuverlässige Wächter für Maschinen. Sie fangen Schmutz, winzige Metallstücke und Wasser aus Ölen, die in Geräten verwendet werden. Wenn diese bösen Dinge im Öl bleiben, können sie das Innere der Maschine schädigen. Dies führt dazu, dass Teile verschleißen, schlecht funktionieren oder sogar vollständig stoppen. Die intelligente Zentrifugalölfiltrationsanlage verwendet eine clevere Spinn- und Vakuummethode. Es zieht feste Stücke, Wasser und Luft aus Ölen. Dadurch bleibt das Öl super sauber. Dies hilft den Maschinen, länger zu halten und besser zu arbeiten.

Sauberes Öl lässt bewegliche Teile reibungslos gleiten. Dies reduziert Energieverschwendung und verhindert, dass Maschinen zu heiß werden. Auch sauberes Öl spart Geld. Sie vermeiden teure Reparaturen und Arbeitsunterbrechungen durch gebrochene Teile. Ölfilter sind wie wachsame Schutzmittel, die Maschinen in großer Form halten.

Mal sehen, was passiert, wenn man Ölfilter nicht oft reinigt.

Folgen der Vernachlässigung der regelmäßigen Filterreinigung

Die Ignorierung der Ölfilterreinigung kann große Probleme verursachen. Schmutziges Öl macht Teile härter reiben. Dies erwärmt Maschinen und verschleißt Schlüsselstücke schneller. Mit der Zeit funktionieren Maschinen weniger gut. Sie könnten sogar plötzlich zusammenbrechen.

Verstopfte Filter können Hydrauliksysteme aktivieren lassen. Dies macht die Arbeit weniger zuverlässig. Außerdem kann Wasser im Öl Rost verursachen. Dies beschädigt Maschinenteile noch mehr. Für Unternehmen, die große Geräte wie Hydraulikpressen oder Turbinenmotoren verwenden, können diese Probleme viel kosten. Die Arbeit stoppt, und Reparaturen sind teuer.

Diese Risiken zeigen, warum gute Reinigungswerkzeuge wichtig sind. Lassen Sie uns untersuchen, wie sie funktionieren.

Wie funktionieren Ölfilterreinigungsmaschinen?

Ölfilterreinigungsmaschinen sind großartige Helfer, um Öle rein zu halten. Sie machen Maschinen besser laufen. Schauen wir uns an, was sie besonders macht und wie sie ihre Arbeit leisten.

Hauptmerkmale von fortgeschrittenen Reinigungsmaschinen

Die heutigen Ölfilterreinigungsmaschinen sind voller sauberer Funktionen. Sie sind einfach zu bedienen und funktionieren wirklich gut. Der OURUN-KOR-60S verfügt über eine intelligente SPS-SteuersystemEs läuft alles automatisch. Es hält auch den Prozess genau im Auge, so dass die Leute nicht viel tun müssen.

Ein weiteres großartiges Merkmal ist der Vakuumspinn-Trick. Sie verwenden keine Wegwerffilter. Dies spart im Laufe der Zeit Geld. Es ist auch freundlich für die Umwelt. Diese Maschinen können alle Arten von Ölen reinigen, auch dicke bis zu 680 mm²/s. Dies macht sie perfekt für viele verschiedene Aufgaben.

Sie können auch viel Schmutz halten. Einige Modelle, wie solche mit Drehtrommeln, können über 1 kg Müll speichern. Dadurch können sie weiterarbeiten, ohne ständige Reinigung zu benötigen.

Schauen wir uns an, wie diese Maschinen Öl Schritt für Schritt reinigen.

Schritte im Reinigungsprozess

Der Prozess beginnt, wenn schmutziges Öl in die Maschine gelangt. Im Inneren arbeiten Drehkraft und Vakuumkraft zusammen. Sie ziehen die schlechten Dinge aus dem Öl. Wasser wird in einem Vakuumraum entnommen. Das Wasser wird zu Dampf und wird herausgeschoben. In der Zwischenzeit werden feste Bits in superpräzisen Filtern oder Drehtrommeln gefangen.

Das gereinigte Öl wird sehr rein. Es erfüllt oft hohe Standards wie NAS1638 5-7 Klassen. Nach der Reinigung geht das Öl zurück in den Tank oder direkt in die Maschine zur Wiederverwendung. Intelligente Systeme mit SPS-Steuerungen Stellen Sie sicher, dass alles reibungslos läuft. Sie brauchen sehr wenig menschliche Hilfe.

Wenn wir wissen, wie diese Maschinen funktionieren, sehen wir, warum sie so nützlich sind.

Was sind die Vorteile der Verwendung einer speziellen Reinigungsmaschine?

Eine spezielle Ölfilterreinigungsmaschine macht die Maschinen besser funktionieren und länger halten. Schauen wir uns die Hauptvorteile an.

Verbesserung der Geräteeffizienz durch saubere Filter

Eine spezielle Ölfilter Reinigungsmaschine hilft Maschinen reibungslos laufen. Es hält das Öl sauber, so dass kein Schmutz durch das System fließt. Dies reduziert Reibung und Wärme, während Maschinen arbeiten.

Sauberes Öl macht Teile wie Lager und Zahnräder leicht zu bewegen. Dies beschleunigt die Arbeit. Es verbraucht auch weniger Energie. Für Unternehmen, die Geld sparen und dem Planeten helfen wollen, ist dies ein riesiger Sieg.

Diese Maschinen können mehr als nur die Effizienz steigern. Außerdem halten die Maschinen länger.

Verlängerung der Lebensdauer von Industriemaschinen

Eine gute Ölfilterreinigungsmaschine hält Maschinen jahrelang im Betrieb. Es entfernt schädliche Stoffe aus Ölen. Dies verhindert, dass Teile wie Pumpen, Ventile und Aktuatoren zu früh verschleißen.

Zum Beispiel bekommt der OURUN-KORS-308C Wasser im Öl auf nur ≤50 ppm. Dies verhindert Rost und andere Probleme, die Maschinenteile schädigen. Diese Probleme können Maschinen im Laufe der Zeit brechen.

Außerdem spart die Nichtverwendung von Wegwerffilter Geld bei der Wartung. Damit laufen die Maschinen unter allen Bedingungen gut. Umweltfreundliche Designs mit Nullverbrauchsfiltration Kosten senken mehr. Sie brauchen nicht immer neue Teile.

Die regelmäßige Verwendung dieser Maschinen hilft Unternehmen, das Beste aus ihren großen Maschinen zu bekommen. Es hält die Arbeit ohne Pausen. Als nächstes sehen wir, wie sie Geld sparen.

Kann eine Ölfilterreinigungsmaschine die Betriebskosten senken?

Ölfilter Reinigungsmaschinen sind großartig, um Geld zu sparen. Sie senken die Kosten, indem sie Maschinen gesund und flüssig halten. Mal sehen, wie sie das tun.

Reduzierung der Wartungskosten durch regelmäßige Reinigung

Die Reinigung von Ölfiltern oft mit einer guten Maschine spart eine Tonne Geld. Der OURUN-KOR-60S verwendet seine Spinnvakuummethode zur Reinigung von Ölen. Es entfernt feste Stücke, Wasser und Luft. Dies verhindert, dass Maschinenteile verschleißen. Dies bedeutet, dass weniger Reparaturen oder neue Teile benötigt werden.

Maschinen wie das OURUN-KORS-308C sauberes Öl, um NAS1638 5-7 Standards zu erfüllen. Sie befreien sich von Schmutz und Metallstücken. Dies verhindert Blockaden und macht die Maschinen besser arbeiten. Regelmäßige Reinigung bedeutet auch, dass Sie im Laufe der Zeit weniger Öl verwenden. Dies senkt die Kosten noch mehr.

Die Einsparung von Fixes ist großartig, aber diese Maschinen halten auch die Arbeit ohne Pausen.

Minimierung von Ausfallzeiten und Steigerung der Produktivität

Ölfilterreinigungsmaschinen helfen, Arbeitsunterbrechungen zu vermeiden. Sie halten die Maschinen gut laufen. Der OURUN-KOR-106C reinigt Wasser, Schmutz und Luftblasen aus Ölen. Dadurch laufen die Maschinen ohne plötzliche Ausfälle. Sauberes Öl macht Teile besser bewegen und verhindert unerwartete Ausfälle.

Intelligente Systeme mit SPS-Steuerung erleichtern die Arbeit. Sie erledigen den Reinigungsprozess selbst. Das OURUN-KOR-60S hat dieses clevere Setup. Es ermöglicht den Arbeitnehmern, sich auf andere Aufgaben zu konzentrieren. Dies hält die Arbeit auf dem richtigen Weg und erhöht, wie viel getan wird.

Lassen Sie uns nun darüber sprechen, was eine erstklassige Ölfilterreinigungsmaschine hervorhebt.

Wo finden Sie zuverlässige Ölfilterreinigungslösungen?

Ourun macht fantastische Ölfilter Reinigungsmaschinen. Sie sind für alle Arten von industriellen Bedürfnissen gebaut. Schauen wir uns an, was sie anbieten.

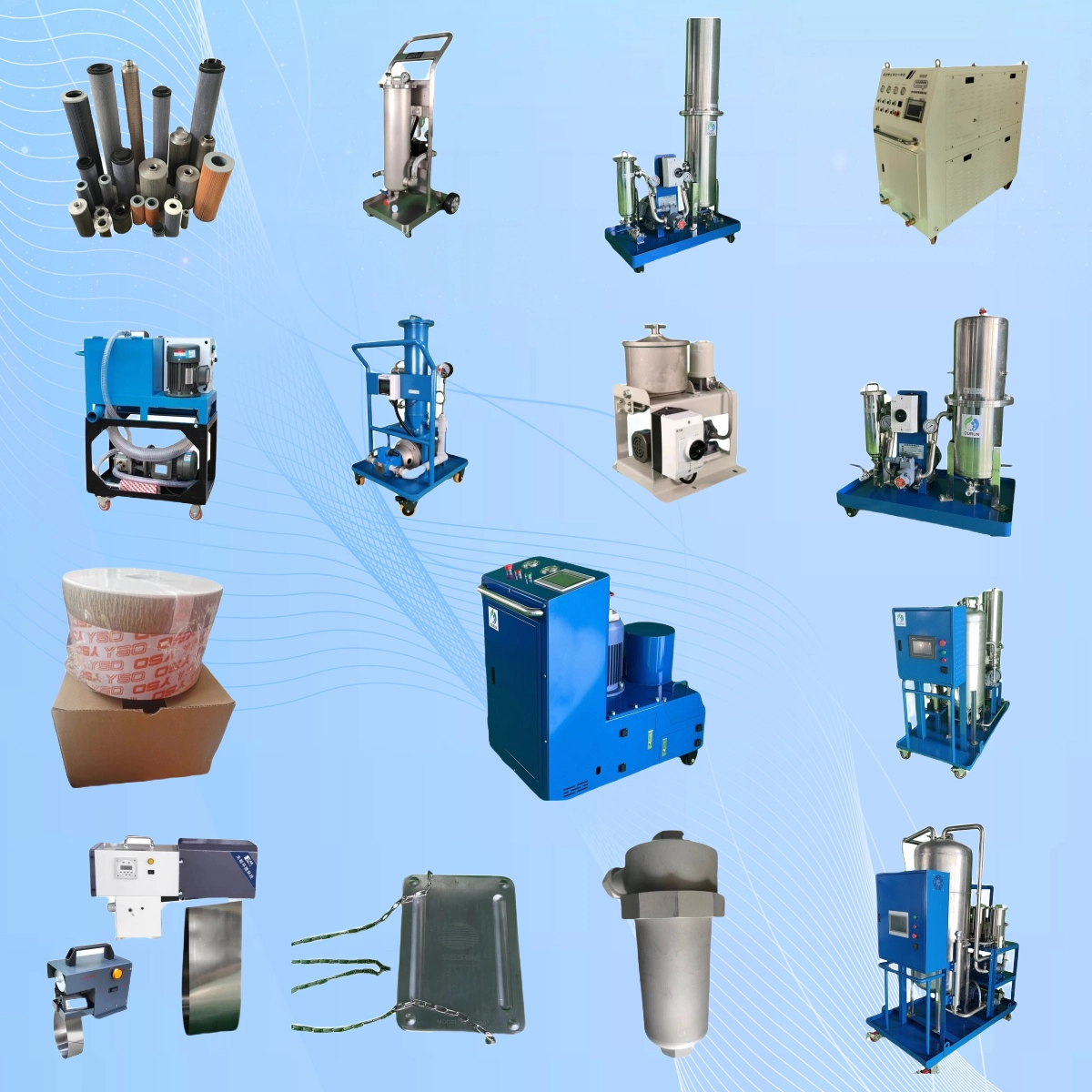

Einführung der innovativen Produkte von Ourun

Ourun bietet eine breite Palette an Ölfilterreinigungsmaschinen an. Die OURUN-KOR Präzisionsölfiltrationsanlage Kundenspezifische Serie Sie können das richtige Modell auswählen. Sie können wählen, basierend darauf, wie viel Öl Sie reinigen müssen und wie viel Schmutz es halten kann.

Die OURUN-JYL-50(20) ist eine gute Wahl. Es ist für Orte gemacht, die oft Öl hinzufügen müssen. Es ist klein, aber hart und bekämpft Rost. Es kann 50 L/min Öl reinigen, ideal für große Arbeitsplätze.

Für Arbeitsplätze, die Wasser entfernen müssen, sind die Vakuumsysteme von Ourun erstaunlich. Der OURUN-KORS-30 verwendet einen Vakuum, um Wasser und Feuchtigkeit abzuziehen. Es bekommt Wasser nach der Reinigung auf nur ≤50 ppm.

Die Maschinen von Ourun sorgen dafür, dass das Öl sauber bleibt und die Maschinen gut laufen. Ihre intelligenten Designs funktionieren für viele verschiedene Aufgaben und liefern zuverlässige und großartige Ergebnisse.

FAQ (häufig gestellte Fragen)

Q1: Wie oft sollten Ölfilter gereinigt werden?

A: Es hängt davon ab, wie die Maschine verwendet wird und wie schmutzig das Öl wird. Sie sollten dem Rat des Herstellers oder Ihrem regelmäßigen Wartungsplan folgen.

Q2: Sind diese Maschinen für alle Arten von Ölen geeignet?

A: Ja, viele Topmodelle arbeiten mit allen Arten von Ölen, wie Hydraulik-, Getriebe- oder Turbinenölen. Die OURUN-KOR Serie kann Öle von 1 bis 680 mm²/s reinigen.

Q3: Was ist Nullverbrauchsfiltration?

A: Es ist ein System, das keine Wegwerffilter oder neue Teile benötigt. Das spart im Laufe der Zeit Geld. Es ist auch gut für die Umwelt.