In busy factory settings, dirty oil causes most machine breakdowns. When you check your equipment, you see more than just metal parts; you see a detailed setup that runs on its vital fluid, which is the lubricating and hydraulic oil. If this fluid gets mixed with water, air, or solid bits, the whole setup could face a major failure. But how do you pick the best way to protect it?

The hard part usually comes down to picking between vacuum cleaning and spinning separation. Both work to make oil clean, but they fix very different issues. Picking the wrong one is not just a small mistake; it can cost a lot in unexpected stops and high repair bills.

Before we get into the details, let me tell you about a company that can guide you through these options. Ourun is not only a maker of equipment; it is a tech company based in the China-Germany Equipment Making Area, focused on custom ways to handle lubrication. We do not push the same machine for every job. Instead, we team up with you to really understand your factory’s exact needs, no matter if you work in metal making, power plants, or chemical work, so we can give you a special guard for your machines. Our goal is to help your work run smoother, greener, and smarter, which means less waste and better output over time.

The Core Physics of Oil Recovery

To choose wisely, you need to see how these two methods deal with dirt in the oil. The aim is to bring the oil back to its starting quality or better, but the way to do that depends on what kind of dirt you have.

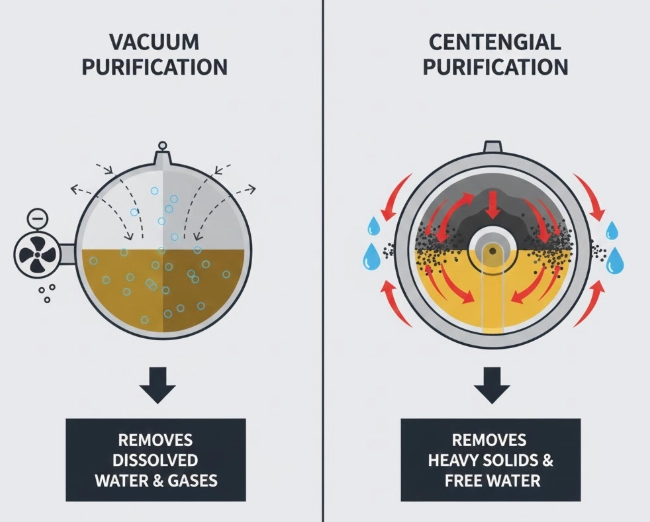

Vacuum cleaning works by pulling out water and gases using low pressure. When you drop the air pressure in a closed space, the point where water and gases turn to steam gets much lower. This lets you heat them out at safe temperatures that do not harm the oil’s basic makeup. It is a careful way to clean oil, targeting the tiny bits of dirt at a deep level.

Spinning cleaning, on the other hand, uses strong spin power, called G-force. By turning the oil very fast, often over 8,000 times a minute, the device uses weight differences to push dirt to the outside. Heavy bits and loose water go to the edge of a container, while the light, clean oil stays in the middle. It is a quick mechanical way to split things, made for big jobs with lots of dirt.

Vacuum Oil Purifiers: The Solution for Deep Dehydration

You should use vacuum methods when water has mixed deeply into your oil. When the oil looks cloudy from blended water, you cannot just spin it out easily; you need to change its state to get rid of it. Vacuum setups are also the best for pulling out hidden gases that lead to bubbles and rust in the oil.

If your factory uses exact machines like turbines or big hydraulic setups, even a little water can cause acid to build and use up helpful additives fast. In such cases, a fixed machine may not work well, especially if your gear is all over a big area or you face a sudden problem.

For these tough spots, the Mobile Vacuum Oil Purifier becomes a key tool. This 400V/50Hz trailer machine is built for fixing problems fast and keeping things running on site. Its easy move lets you take strong vacuum power right to where the issue is, dealing with big amounts of oil in far or hard factory areas. It does more than just clean; it brings back the oil’s strength against electricity and its steady makeup right away, which helps prevent bigger breakdowns and keeps your work flowing without big interruptions.

Centrifugal Oil Purifiers: The Heavy-Duty Solid Remover

Spinning separators work best when you face big, obvious dirt. If your oil is full of thick mud, metal scraps, or lots of loose water, a vacuum machine might get too full or need fixing all the time. Spinning units are made for these rough jobs.

You often see these in areas like digging for minerals, steel factories, or ship building. Since they do not use thin screens for the first clean, they cost little on parts that wear out in the start of the process. They handle thick oils and liquids well that would clog normal screens fast. But while they are quick and strong, they may not get the oil clean enough for the strict ISO rules needed in new high-pressure hydraulic parts, so you might need extra steps to meet those standards.

The Critical Role of Precision Filtration

No matter if you go with vacuum or spinning, neither method fixes everything alone. To hit the exact ISO 4406 clean levels that machine makers require today, you need a last fine clean step. Small solid bits, especially those from 3 to 5 microns, quietly harm bearings and seals over time.

Facts show that about 80% of hydraulic setup failures come from dirty oil. Even oil that seems clean can hold tiny rough bits that wear parts like sand in water. This is why top parts decide if your factory makes good money or not, as clean oil directly ties to less repairs and more steady work.

Using Precision Filter Elements makes sure your oil gets pure enough to guard key parts like seals and control valves. These parts are set to manage the right speeds and strengths in factory uses, grabbing the small bits that spinning or basic vacuum might let pass. By adding strong filtering, you can make your hydraulic oil last from two years to five or more, which cuts your full costs a lot and helps your budget stay steady year after year.

Deciding the Best Path for Your Operation

The pick is not always about which method is top, but which matches your type of dirt. To choose, you have to check what is really harming your oil.

If you work with precise machines where water causes rust, vacuum is the better pick. It gives the chemical fix needed for steady oil over time. If your work has heavy wear with dirt and water coming in all the time, spinning gives the speed to handle the load.

In many new factories, the top setup mixes both. You could use spinning for rough clean of old oils and a moving vacuum for fine care of working systems. This step-by-step way makes sure your oil is always at its best, not just okay, leading to fewer issues and better daily runs that support your goals for growth and reliability.

Profitability Through Professional Oil Management

Putting money into the right cleaning tech is a clear way to earn more. When you cut dirt, you save on new oil costs, and that save is big, often dropping oil buys by two-thirds. But the true win comes from the unseen gains that build up over months.

With clean oil, you can cut surprise stops by up to 80%. In a busy plant, skipping even one day of halt saves thousands in lost work. Also, clean oil lowers rub and betters power move, which can raise your hydraulic setup’s work rate by 3% to 5%, meaning more product out with the same input and less energy waste.

The help after the buy matters as much as the machine. Good service goes beyond just sending it; it covers checking your oil tests, setting right speeds for your area’s power, and teaching your team how to use it on site. This keeps your buy working well for years, turning a one-time cost into long-term savings that boost your whole operation’s strength and cut risks from poor upkeep.

FAQ

Q: Can a centrifugal purifier remove dissolved water from oil?

A: No. Centrifugal purifiers are effective only at removing free water and heavy solids through density separation. To remove dissolved or emulsified water at a molecular level, you must use a vacuum oil purifier which utilizes dehydration and degassing technology.

Q: How do I know when to replace my precision filter elements?

A: You should monitor the pressure differential across the filter. As the element captures more contaminants, the pressure required to push oil through increases. Most professional systems include a gauge or an intelligent monitoring system to alert you when the element has reached its capacity.

Q: Is it more cost-effective to buy new oil or purify the old oil?

A: In almost all industrial cases, purification is significantly more cost-effective. The cost of regenerating used oil to “new” standards is typically only about one-third of the market price for new oil. Additionally, purification eliminates the environmental and logistical costs associated with waste oil disposal.