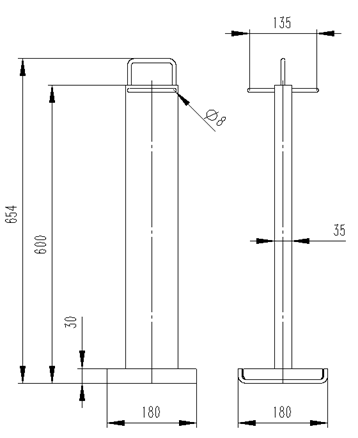

This series of products is currently divided into two models, with heights of 300mm and 600mm, which can be selected appropriately according to different working conditions. The overall dimensions of this product are as follows:

2. Product use

It is used to adsorb and remove chip powder mixed in various working machine lubricating oils, hydraulic oils and other oils to improve the cleanliness of the lubricating oil.

3. Product features

1. It uses high-strength NdFeB magnets with strong performance, no consumables, and no power consumption. A one-time investment will benefit you for life, and its service life is more than 20 years.

2. The design of a cleaning tray wrapped around the permanent magnet column makes cleaning easy. Hold the handle and gently lift the cleaning tray. After removing the adsorbed impurities and iron filings, you can easily put the cleaning tray back onto the magnet column. It is extremely convenient to use and maintain.

3. The entire equipment is designed with a casing made of stainless steel 304, with brushed surface treatment, beautiful appearance, and excellent corrosion resistance, ensuring the durability of the equipment.

4. The equipment’s temperature resistance can reach 100℃.

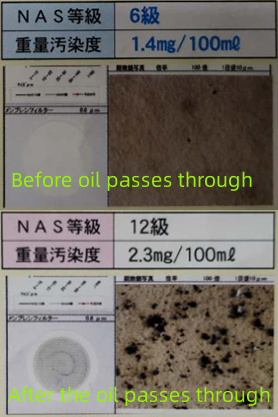

4. Purification effect

This product uses the strong magnetic field generated by the permanent magnet to effectively absorb iron filings and impurities in the oil flowing near it. The effect is shown in the figure below:

Before the oil passes through After the oil passes through

5. How to use

Place this equipment evenly in the fuel tank. The layout is as shown in the figure below. The vertical distance between two adjacent equipment is 100~120mm, and the distance between the equipment and the side wall of the fuel tank should be more than 100mm.

6. Product maintenance

Clean the oil regularly, and it is recommended to clean it once a month (if the oil pollution is serious, the cleaning cycle can be shortened according to the actual situation), so that the equipment can run at its best and provide you with the best decontamination effect.

7. Precautions

1. Keep away from computer watches, etc. to avoid unforeseen damage caused by strong magnetic fields to your computer watches.

2. The fuel tank should be placed away from instruments, such as liquid level gauges, heating devices, temperature displays, pumps, pressure gauges, etc.

3. Place the fuel tank in a location where the oil flows smoothly, away from the oil inlet and outlet.

4. When transporting, handle them individually, not more than one.

5. When overhauling the oil pump and cleaning the oil suction filter, remove the contaminants on the surface of the separator at the same time. After removal, it will be effective again.